Knotted wheel brushes: the most important principles

Wheel brushes from PFERD TOOLS are top-quality tools for work on surfaces. We make a distinction between knotted and crimped wheel brushes.

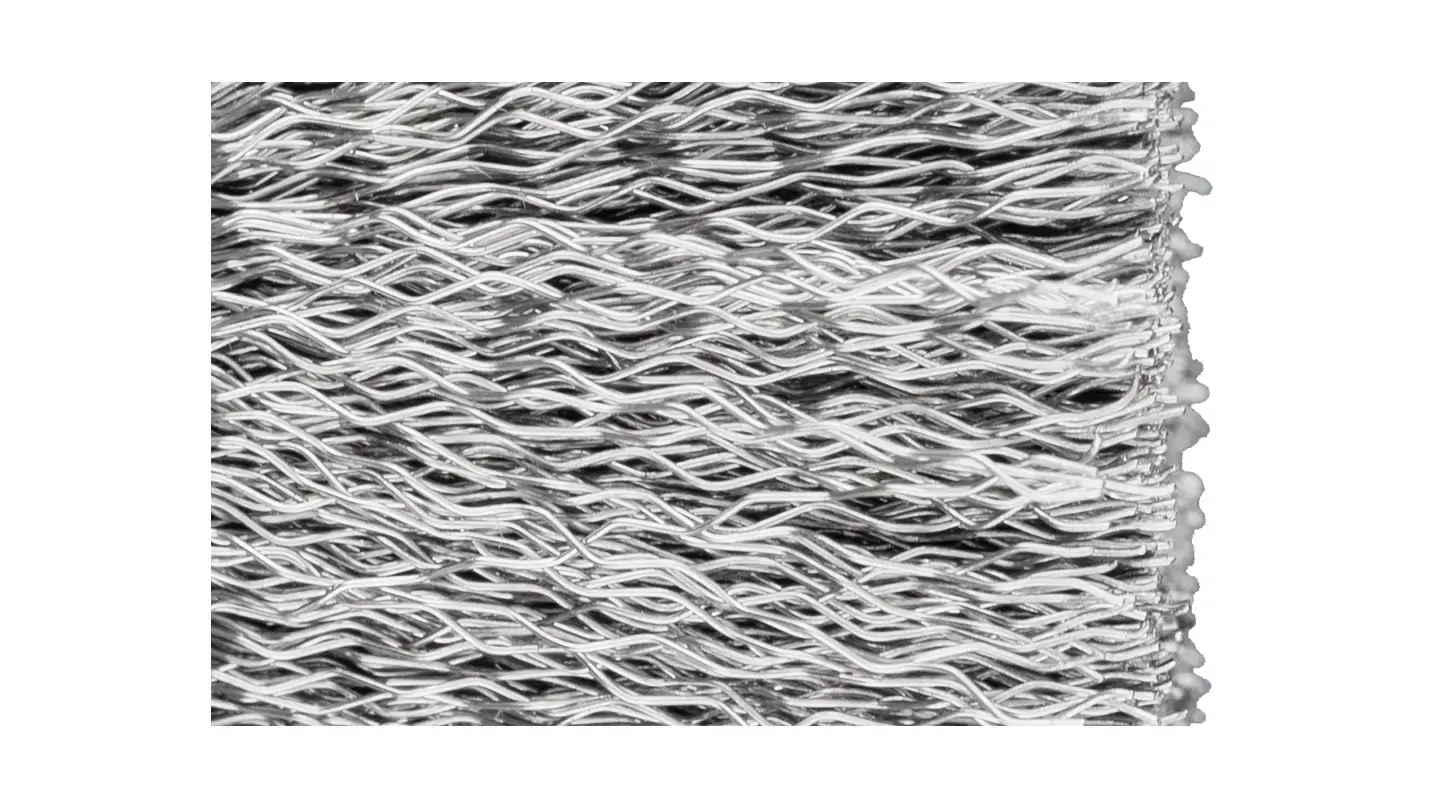

Crimped wheel brushes differ from knotted wheel brushes in that they have an open wire structure for flexible use with a slight brushing effect.

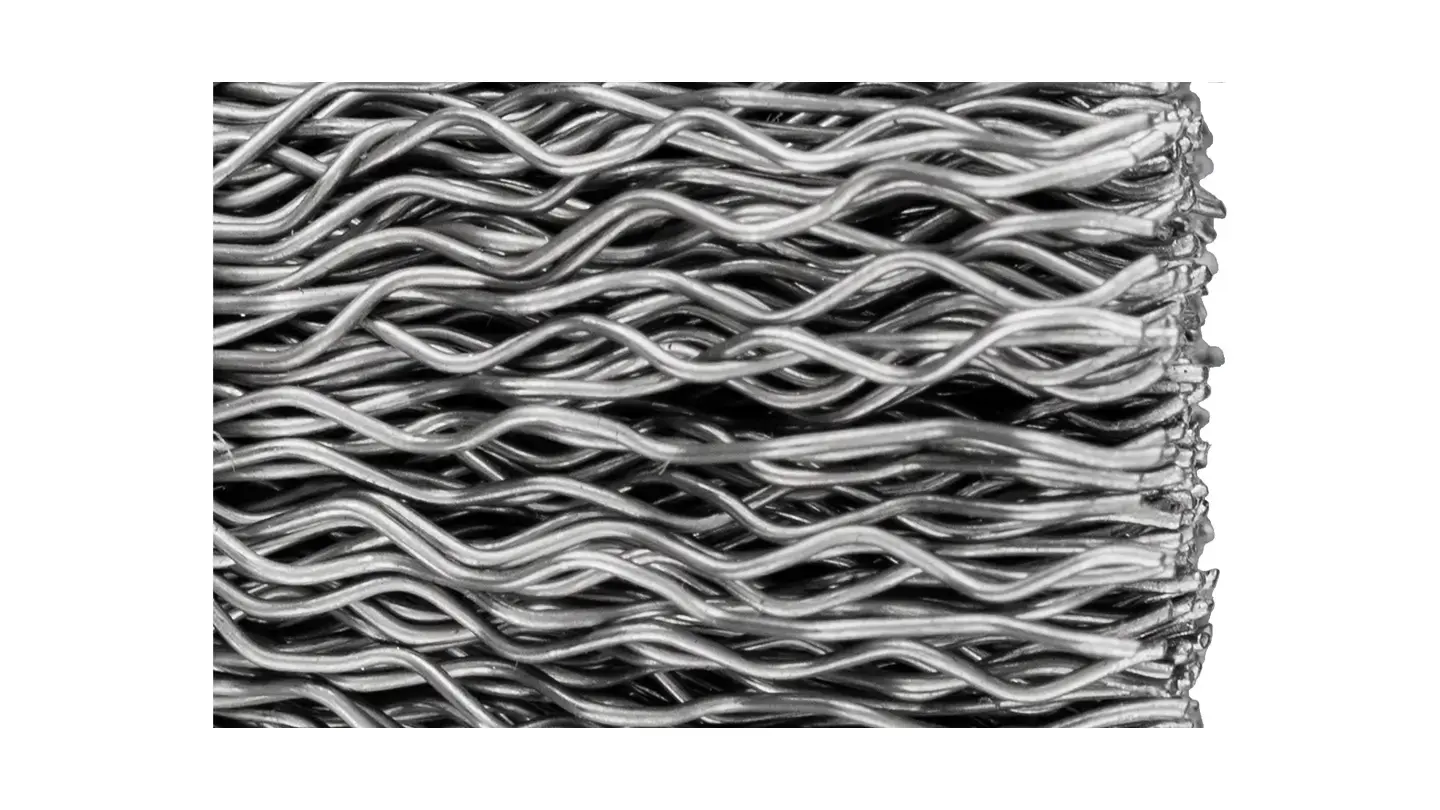

Knotted wheel brushes are suitable for aggressive brushing work on account of the very stiff wire knots.

How you benefit from knotted wheel brushes from PFERD TOOLS

Knotted wheel brushes from PFERD TOOLS are ideal for intense work on metal surfaces and stand out with their impressively sturdy design and aggressive stock removal rate thanks to their stiff wire knots. The models differ in their mounting system, for example arbor hole, thread and shank.

PFERD TOOLS ensures the very highest quality standards and precise performance. With its Pipeline and COMBITWIST models plus the enhanced COMBITWIST HD, PFERD TOOLS offers a number of different knots to suit specific applications.

Where are knotted wheel brushes used?

Knotted wheel brushes are suitable for the following applications:

- Deburring

- Removing paint

- Derusting

- Cleaning

- Removing oxide layers

- Work on fillet welds

- Work on weld seams

- Work on root seams

- Surface work

- Brushing work in pipeline and container construction.

- They can also be used on complicated components such as cylinder heads or gear toothing.

What drives are wheel brushes used on?

Depending on the specific version, wheel brushes can be used on angle grinders, straight grinders, flexible shaft drives, power drills or stationary machines such as bench grinders and robots.

As from a diameter of 180 mm, PFERD TOOLS' knotted wheel brushes are only suitable for use on stationary machines.

Which materials can be machined using wheel brushes?

- Steel

- Stainless steel (INOX)

- Aluminium

- Bronze

- Cast iron

- Plastics

- Titanium and titanium alloys

- Non-ferrous metals

Which filament materials are available for knotted wheel brushes?

- Wheel brushes with knotted steel wire are suitable for robust metalworking tasks such as derusting.

- Knotted INOX wheel brushes with stainless steel wire (1.4310) are used for corrosion-resistant applications on stainless steel (e.g. V2A and V4A).

- Brushes with the filament material stainless steel wire (INOX) diamond (DIA) are suitable for particularly aggressive brushing work. They are recommended primarily for materials with high material strength.

Advantages of the different filament materials for knotted wheel brushes

Steel wire (ST) – advantages/properties:

- PFERD TOOLS special wire with high tensile strength and bending fatigue strength.

- Guarantees a long tool life, even for extreme brushing applications.

- Temperature resistance: up to 300°C

Stainless steel wire (INOX) – advantages/properties:

- Wire quality 1.4310 (V2A): stainless ; does not leave corroding residues on the workpiece.

- Used with low rotational speeds , compared to steel wire.

- PFERD TOOLS brushes with INOX filament are usually degreased.

- Temperature resistance: up to 450°C

Stainless steel wire (INOX) diamond (DIA) – advantages/properties:

- Particularly well suited to applications that place particular demands on the aggressiveness of the brush.

- Primarily used on materials with high material strength.

Optimum rotational speeds for knotted wheel brushes

Thanks to their high-quality workmanship, PFERD TOOLS' knotted brushes guarantee durability and the highest levels of occupational safety.

Observe the recommended rotational speeds and avoid pressing down with a higher contact pressure so as to ensure optimum results and extend the tool life.

Download the overview of optimum rotational speeds for knotted wheel brushes now.

Download

COMBITWIST HD knotted wheel brush

Extremely high filament density and reinforced wire filament not only ensure a tool life that is at least three times longer than the standard COMBITWIST version, but also enable greater stock removal. The COMBITWIST HD brushes are ideal for heavy-duty work in the metalworking industry.

Advantages:

- Extremely high filament density for optimum tool life.

- High level of comfort thanks to smooth running with no brush recoiling.

- Suitable for work on corners and edges as the knots are less likely to unravel.

- Aggressive brushing effect due to the very stiff wire knots.

- Very good corrosion resistance.

- The brush is degreased and does not leave any oil residue on the workpiece.